Brush Machine Safety Standards: Protecting Workers

Brush Machine Safety Standards: Protecting Workers

Blog Article

In the dynamic world of manufacturing, ensuring the safety of workers is a top priority, especially in industries where machines run continuously and handle potentially hazardous materials. Brush machines, essential for producing a variety of bristle products, require adherence to stringent safety standards to protect those operating them. As factories strive to enhance productivity and efficiency, integrating safety measures becomes an indispensable part of the process.

Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd. stands as a testament to this commitment to safety. With 37 years of production experience, the company not only specializes in the innovative design and manufacturing of 2-5 axis machines but also emphasizes the importance of creating a safe working environment. By adhering to safety standards and best practices, they ensure that their equipment is not only efficient but also designed with the well-being of the operators in mind.

Overview of Brush Machine Safety Standards

Brush machines are essential in manufacturing processes, and ensuring their safe operation is vital for protecting workers. Safety standards for brush machines are designed to minimize risks associated with machinery, such as unexpected startup, moving parts, and electromagnetic hazards. These standards often encompass requirements for equipment design, installation, and maintenance, ensuring that machines are not only effective but also safe for operators.

Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd. has established itself as a leader in the industry with its extensive experience of 37 years. The company's commitment to safety aligns with international standards, reflecting a deep understanding of the technical requirements necessary for brush machinery. Implementing robust safety protocols ensures that their machines provide a secure working environment while enhancing productivity.

Adopting stringent safety standards involves regular training for employees and thorough evaluations of equipment. This includes adhering to guidelines that dictate machine guarding, emergency stop mechanisms, and proper operation procedures. By prioritizing worker safety alongside machine performance, companies like Jiangmen Meixin contribute to a culture of safety and responsibility within the manufacturing sector.

Importance of Worker Protection

Worker protection is paramount in any manufacturing environment, especially in factories that operate machinery like brush making machines. Ensuring the safety of employees not only helps to prevent accidents and injuries but also fosters a culture of respect and care within the workplace. When workers feel secure, they are more likely to be productive and engaged, ultimately benefiting the entire organization. Companies such as Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd. understand this principle and prioritize the implementation of rigorous safety standards.

In addition to safeguarding employees from physical harm, strong safety measures also enhance the company's reputation. Clients and stakeholders are increasingly aware of corporate responsibility and ethical practices. A commitment to worker safety showcases a company's dedication to its workforce and can lead to increased customer loyalty and trust in the brand. The long history of Jiangmen Meixin in producing advanced machines demonstrates a commitment not just to quality products, but to the welfare of the individuals operating them.

Furthermore, adhering to safety standards can help reduce costs associated with workplace accidents. Injuries can lead to downtime, increased insurance premiums, and potential legal issues, all of which can have significant financial implications for a business. By investing in safety training and properly maintained equipment, companies can minimize these risks and create a more sustainable and profitable operation. Ultimately, the importance of worker protection extends beyond compliance; it is a fundamental aspect of operational excellence in the manufacturing sector.

Jiangmen Meixin's Commitment to Safety

Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd. recognizes that the safety of its workers is paramount in the brush machine manufacturing industry. With 37 years of experience, the company has developed comprehensive safety protocols designed to protect employees while maximizing productivity on the factory floor. This commitment to safety is reflected in their regular safety training sessions, ensuring all workers are well-informed about machine operations and emergency procedures.

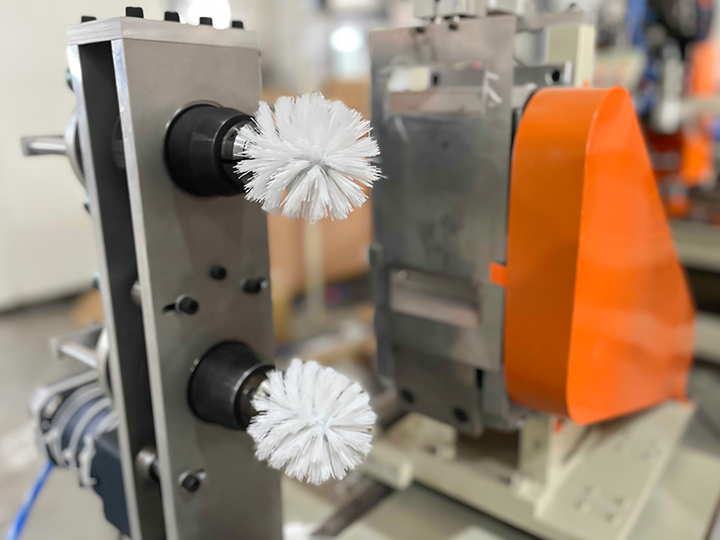

The company employs state-of-the-art technology to enhance safety measures in their 2-5 axis machines. These machines are equipped with advanced safety features such as emergency stop buttons, guarding systems, and automated shut-off mechanisms to prevent accidents. By integrating these safety elements into their designs, Jiangmen Meixin not only meets industry standards but also fosters a culture of safety that prioritizes the well-being of its employees.

Furthermore, Jiangmen Meixin actively seeks feedback from its workforce regarding safety practices and machine operations. This open communication channel enables continuous improvement in safety protocols and machine performance. By involving employees in safety discussions, the company cultivates a strong sense of responsibility and ownership among its workers, ultimately leading to a safer and more efficient workplace.

Industry Best Practices

In the brush machine manufacturing industry, adhering to safety standards is paramount to ensure the well-being of workers. Companies like Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd. set the standard by implementing rigorous safety protocols throughout their production processes. This includes regular safety training sessions for employees, focusing on the proper usage of machinery and the importance of personal protective equipment. By fostering a culture of safety, companies can significantly reduce the risk of accidents and enhance worker morale.

Another best practice is the integration of advanced technology in manufacturing processes. The use of 2-5 axis machines not only improves efficiency but also helps minimize human error. With 37 years of production experience, Jiangmen Meixin has effectively leveraged automation and precision machinery, which allows for safer operations while maintaining high quality. Automated systems often come with built-in safety features that reduce the likelihood of workplace injuries, making them an essential aspect of modern manufacturing practices.

Regular maintenance and safety audits are crucial for sustaining high safety standards in brush machine factories. These audits should assess both machinery and work environments to identify potential hazards before they lead to accidents. Jiangmen Meixin exemplifies this practice by conducting thorough inspections and updates to their safety protocols based on the latest industry standards. Continuous improvement and adaptation to new safety regulations ensure that the workforce remains protected and that the company maintains its commitment to excellence in manufacturing.

Meixin Automatic Brush Making Machine

Future Trends in Brush Machine Safety

The ongoing advancements in technology are poised to significantly enhance brush machine safety standards. As manufacturers like Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd. increase the automation within their machines, incorporating smart sensors and AI-driven monitoring systems will become more prevalent. These innovations can help anticipate potential hazards, enabling proactive measures to reduce risks before they affect workers. Enhanced data collection and analytics will also support the development of tailored safety protocols for specific machine types and working environments.

Another trend is the emphasis on worker training and education regarding machine safety. As brush machines become more technologically advanced, training programs will need to evolve. Companies will increasingly focus on immersive training techniques, such as virtual reality simulations, to ensure that employees understand the complexities of operating sophisticated machinery. This approach not only promotes a safer workplace but also empowers workers with the knowledge necessary to respond effectively in case of emergencies.

Regulatory bodies are likely to impose stricter regulations on safety standards for brush manufacturing machinery. As industries continue to recognize the importance of protecting workers, there will be a push for more detailed compliance requirements. Manufacturers will need to stay ahead of these changes by continuously updating their safety measures and adhering to best practices in machine design and operation. The collaboration between companies like Jiangmen Meixin and regulatory agencies will play a crucial role in shaping a safer future for brush machine factories.

Report this page